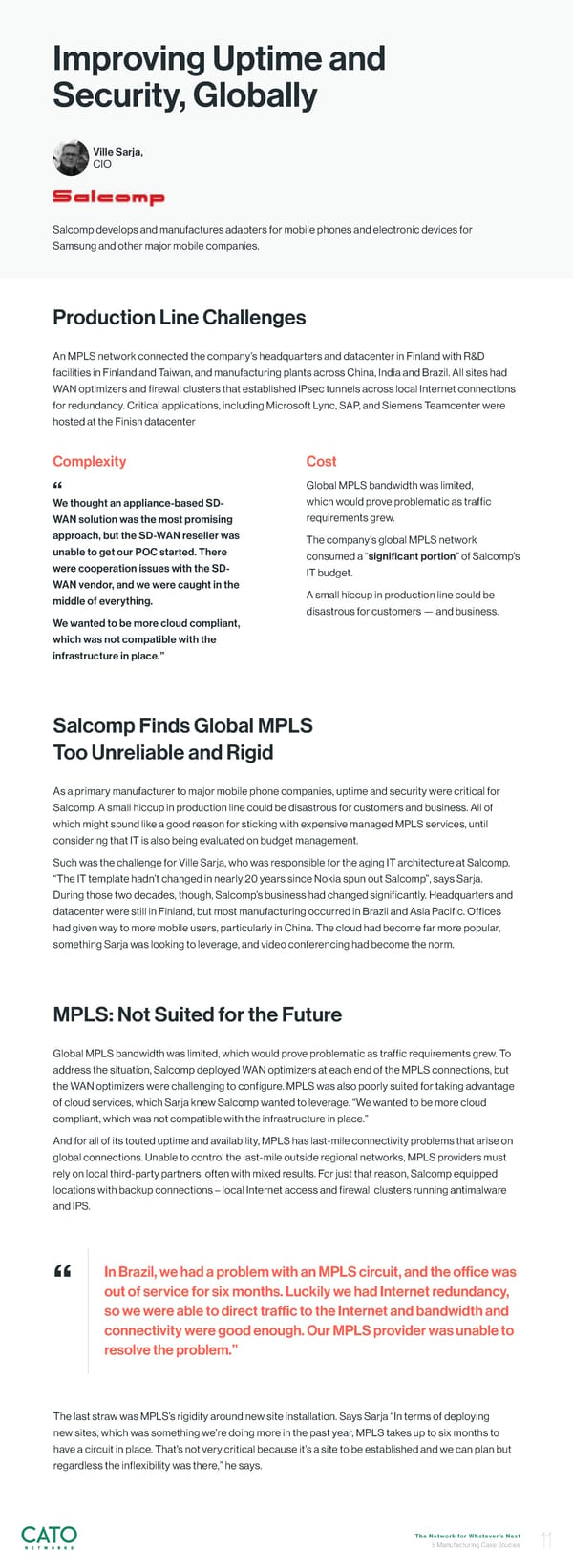

Improving Uptime and Security, Globally Ville Sarja, CIO Salcomp develops and manufactures adapters for mobile phones and electronic devices for Samsung and other major mobile companies. Production Line Challenges An MPLS network connected the company’s headquarters and datacenter in Finland with R&D facilities in Finland and Taiwan, and manufacturing plants across China, India and Brazil. All sites had WAN optimizers and firewall clusters that established IPsec tunnels across local Internet connections for redundancy. Critical applications, including Microsoft Lync, SAP, and Siemens Teamcenter were hosted at the Finish datacenter Complexity Cost “ Global MPLS bandwidth was limited, We thought an appliance-based SD- which would prove problematic as traffic WAN solution was the most promising requirements grew. approach, but the SD-WAN reseller was The company’s global MPLS network unable to get our POC started. There consumed a “significant portion” of Salcomp’s were cooperation issues with the SD- IT budget. WAN vendor, and we were caught in the middle of everything. A small hiccup in production line could be disastrous for customers — and business. We wanted to be more cloud compliant, which was not compatible with the infrastructure in place.” Salcomp Finds Global MPLS Too Unreliable and Rigid As a primary manufacturer to major mobile phone companies, uptime and security were critical for Salcomp. A small hiccup in production line could be disastrous for customers and business. All of which might sound like a good reason for sticking with expensive managed MPLS services, until considering that IT is also being evaluated on budget management. Such was the challenge for Ville Sarja, who was responsible for the aging IT architecture at Salcomp. “The IT template hadn’t changed in nearly 20 years since Nokia spun out Salcomp”, says Sarja. During those two decades, though, Salcomp’s business had changed significantly. Headquarters and datacenter were still in Finland, but most manufacturing occurred in Brazil and Asia Pacific. Offices had given way to more mobile users, particularly in China. The cloud had become far more popular, something Sarja was looking to leverage, and video conferencing had become the norm. MPLS: Not Suited for the Future Global MPLS bandwidth was limited, which would prove problematic as traffic requirements grew. To address the situation, Salcomp deployed WAN optimizers at each end of the MPLS connections, but the WAN optimizers were challenging to configure. MPLS was also poorly suited for taking advantage of cloud services, which Sarja knew Salcomp wanted to leverage. “We wanted to be more cloud compliant, which was not compatible with the infrastructure in place.” And for all of its touted uptime and availability, MPLS has last-mile connectivity problems that arise on global connections. Unable to control the last-mile outside regional networks, MPLS providers must rely on local third-party partners, often with mixed results. For just that reason, Salcomp equipped locations with backup connections – local Internet access and firewall clusters running antimalware and IPS. In Brazil, we had a problem with an MPLS circuit, and the o昀케ce was “ out of service for six months. Luckily we had Internet redundancy, so we were able to direct tra昀케c to the Internet and bandwidth and connectivity were good enough. Our MPLS provider was unable to resolve the problem.” The last straw was MPLS’s rigidity around new site installation. Says Sarja “In terms of deploying new sites, which was something we’re doing more in the past year, MPLS takes up to six months to have a circuit in place. That’s not very critical because it’s a site to be established and we can plan but regardless the inflexibility was there,” he says. The Network for Whatever’s Next 5 Manufacturing Case Studies 11

Cato Networks Manufacturing Page 10 Page 12

Cato Networks Manufacturing Page 10 Page 12